Bespoke Camera Technology

Bespoke Camera

Technology

Bespoke Camera Technology Services:

Special Pipeline Camera (SPC-15)

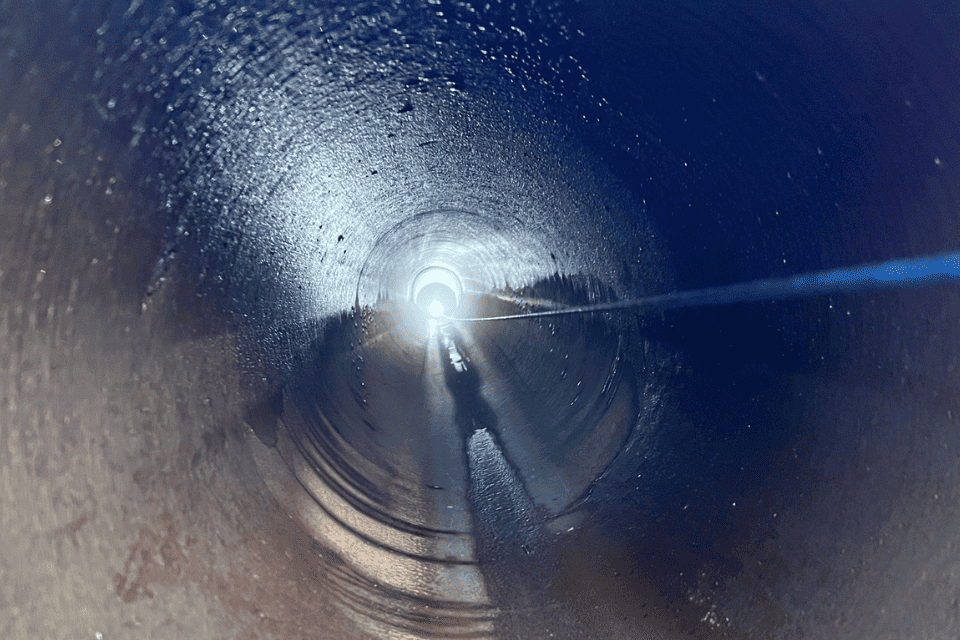

This camera system can reach places far beyond the capabilities of any other cameras available on the global market. The SPC-15 camera is designed to be used in difficult to access places with the capability to withstand extreme conditions. This camera can operate in any type of pipe from water, sewer and industrial wastewater through to oil and gas. It can also operate in fully submerged rock shafts and bore holes on land and at sea.

It is also equipped with a tracking sonde capable of being used in steel pipes.

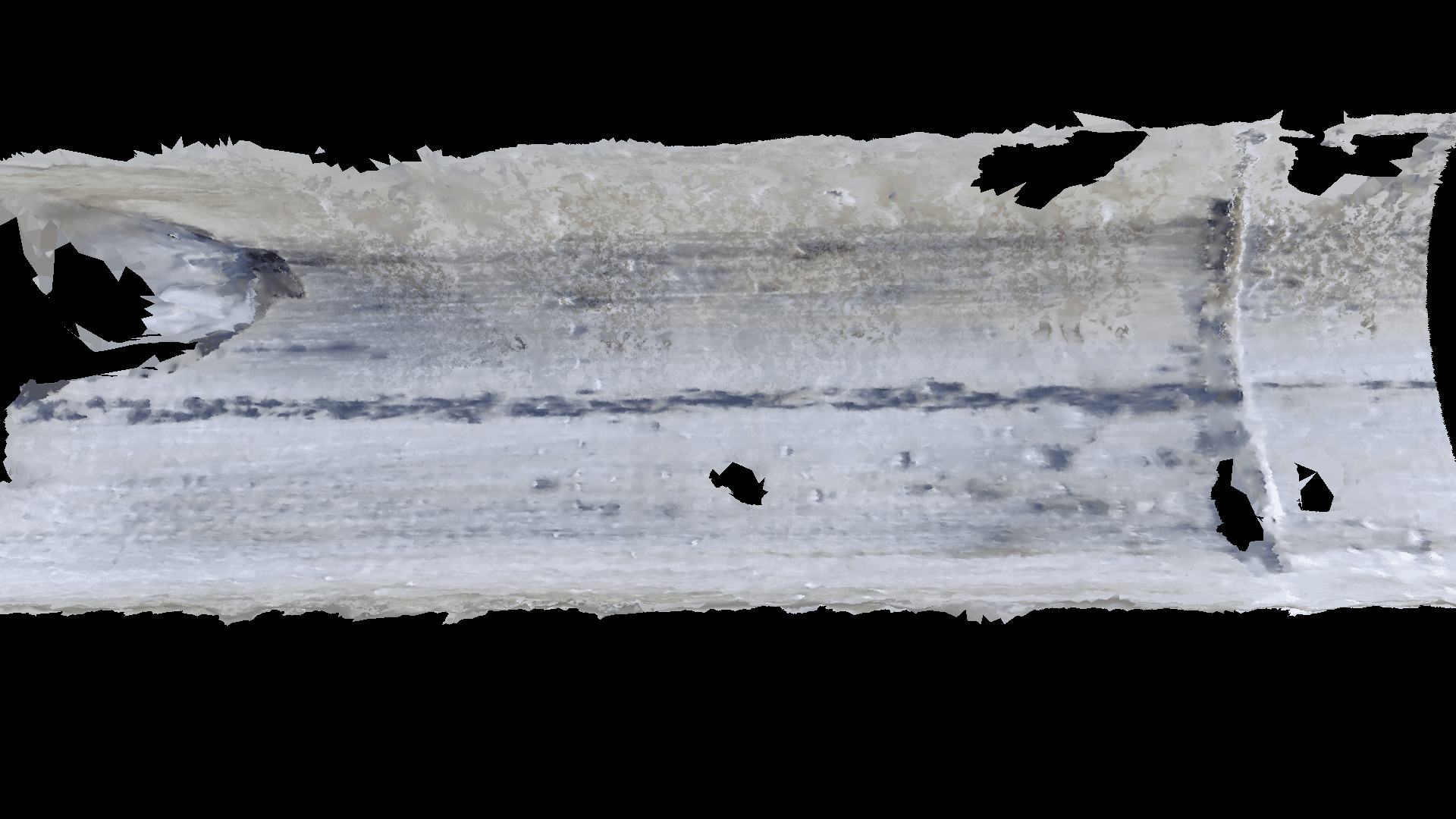

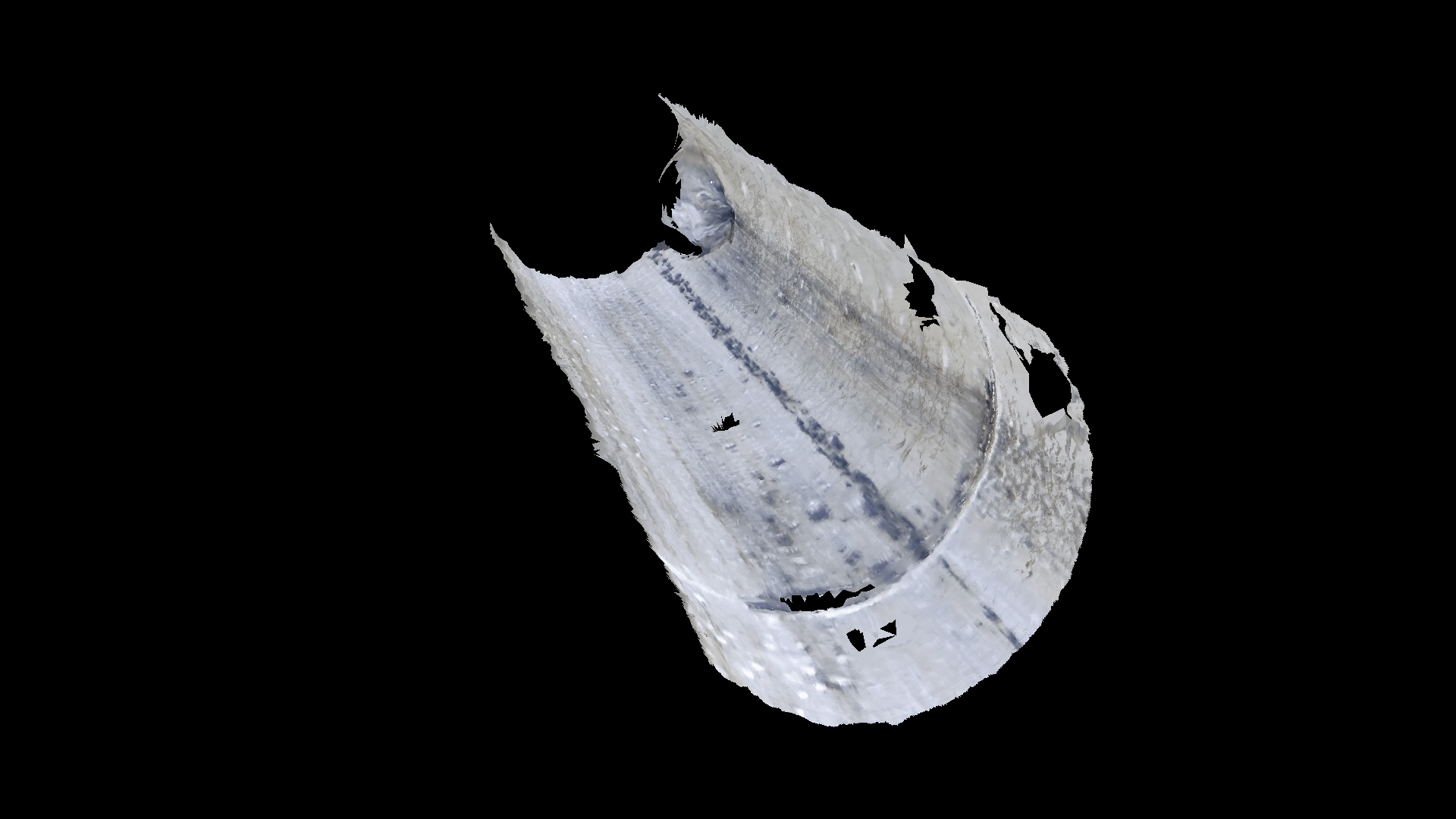

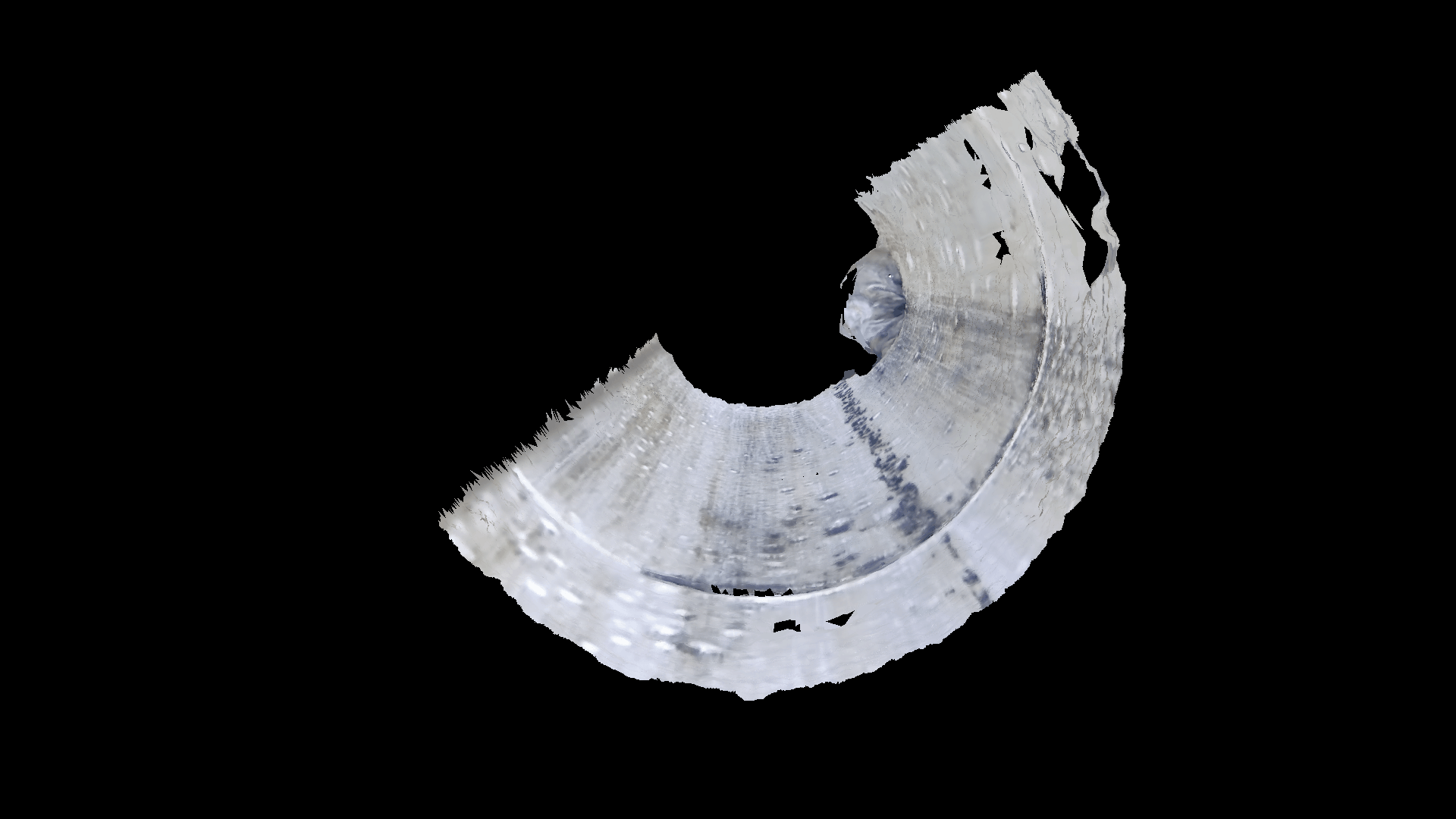

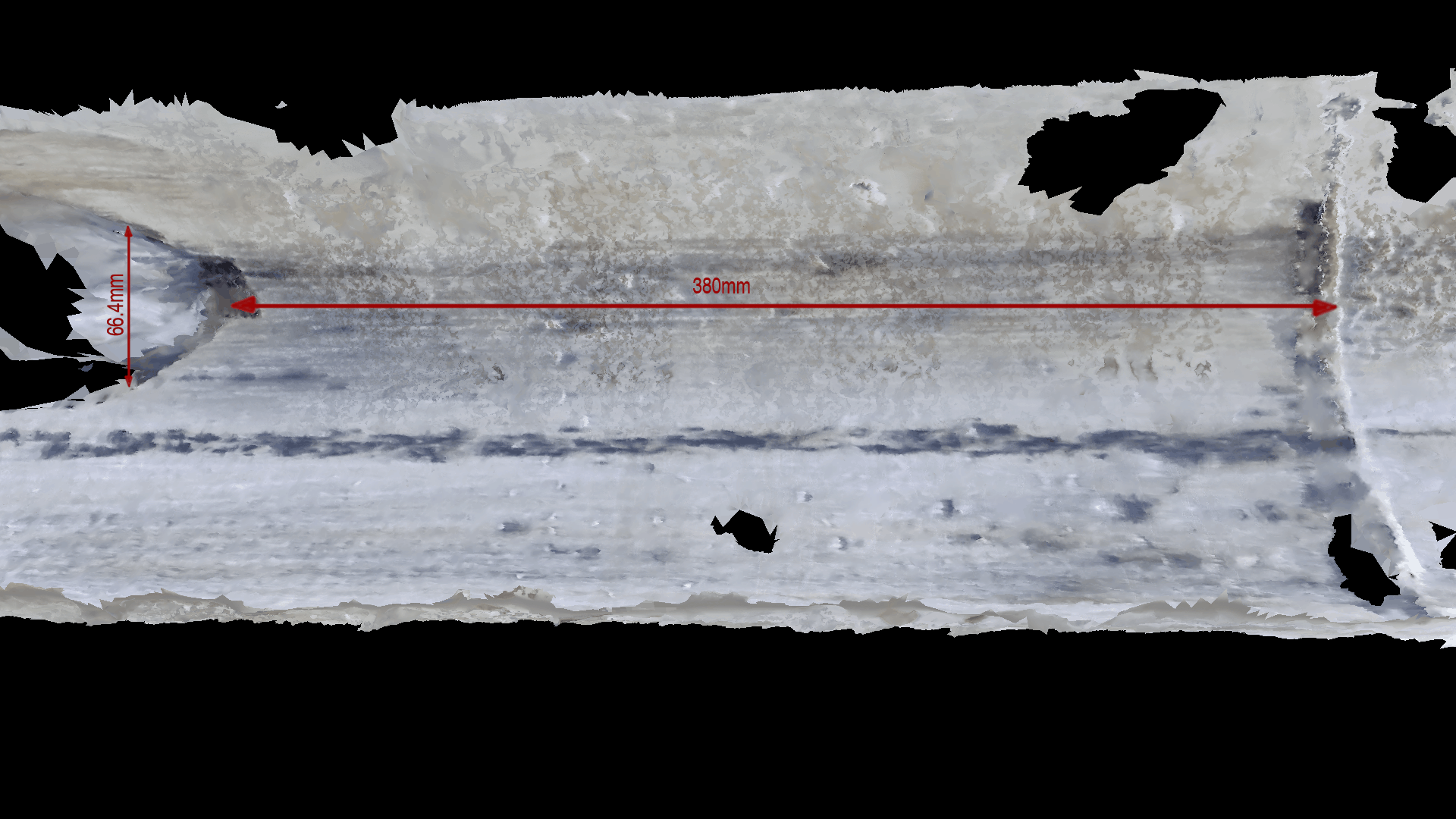

The camera system is capable of POI 3D scanning and for sections of the pipes that need closer inspection, these can be converted to 3D geometry when the camera is travelling at a slower rate. The scanned data obtained from the camera system needs to be analysed and processed by our team of engineers.

With the use of sophisticated 3D scanning software, data can be converted into 3D models or unwrapped on to a flat 2D image of the pipe or shaft. In addition to this, the camera can measure anomalies in the pipeline to 0.01mm which enables extremely accurate data for pipe internal diameters, angles of a pipe bend or the extent of a misaligned joint. It can provide the location and measurements of cracks and fissures in rock or be used to measure the volume of encountered obstacles.

-

Length 345mm

-

Diameter 49mm

-

Weight 1100g

-

Forward light 2734 lumen

-

Battery life 16h

-

Battery capacity 15,600mAh

-

Recording time in HD1080p 8h

-

Memory card 128gb

-

Optimal frame rate 60fps

-

Pressure rating 500psi (peak 600psi)

-

Self levelling

-

Anodized aluminium body (safe to use around explosive gasses)

-

Fully waterproof body

-

High quality video at HD 1080 at 60fps, HD 3k at 60fps, or UHD 4k at 50fps.

Fibre Optic Cam

The Fibre Optic Cam was initially developed for the Mt Albert sludge line repair project in Wellington. Two DN150 sludge pipes both 1.8km long concrete lined ductile iron pipes. Due to a seismic event towards the end of 2019, it was discovered that both pipes had broken and were pumping sludge into an interceptor tunnel. Neither of the sludge pipelines could be used forcing Wellington Water to run a fleet of vacuum trucks 24 hours a day, 7 days a week to transport the sludge at a cost to ratepayers of over $600,000.00 per week. The pipes were not able to be accessed by contractors, and Wellington Water had no way of inspecting and assessing the 1.8km long pipes. More project information can be found here.

The Fibre Optic Camera H&B developed can give a full live stream up to 3km of pipeline and it can also 3D scan and measure items of interest to 0.01mm accuracy. The high level of quality and accuracy that this camera system has enables thorough pipeline assessments to occur giving clients access to condition assessments of assets that has previously not been achievable until now.

Rail Cam

Floor Mounted Tunnel Cam

Mini Swabbing Camera

Miniature Live Feed Inspection Camera and VR Headset

This camera head and lighting housing measures only 9.5mm diameter with a 100m long 4.86mm cable.

Colour image with adjustable lighting

VR headset & viewing screen

This camera was initially developed for camera inspecting 12mm diameter frozen pipelines under cold stores which had experienced slab heave after the heating system failed.

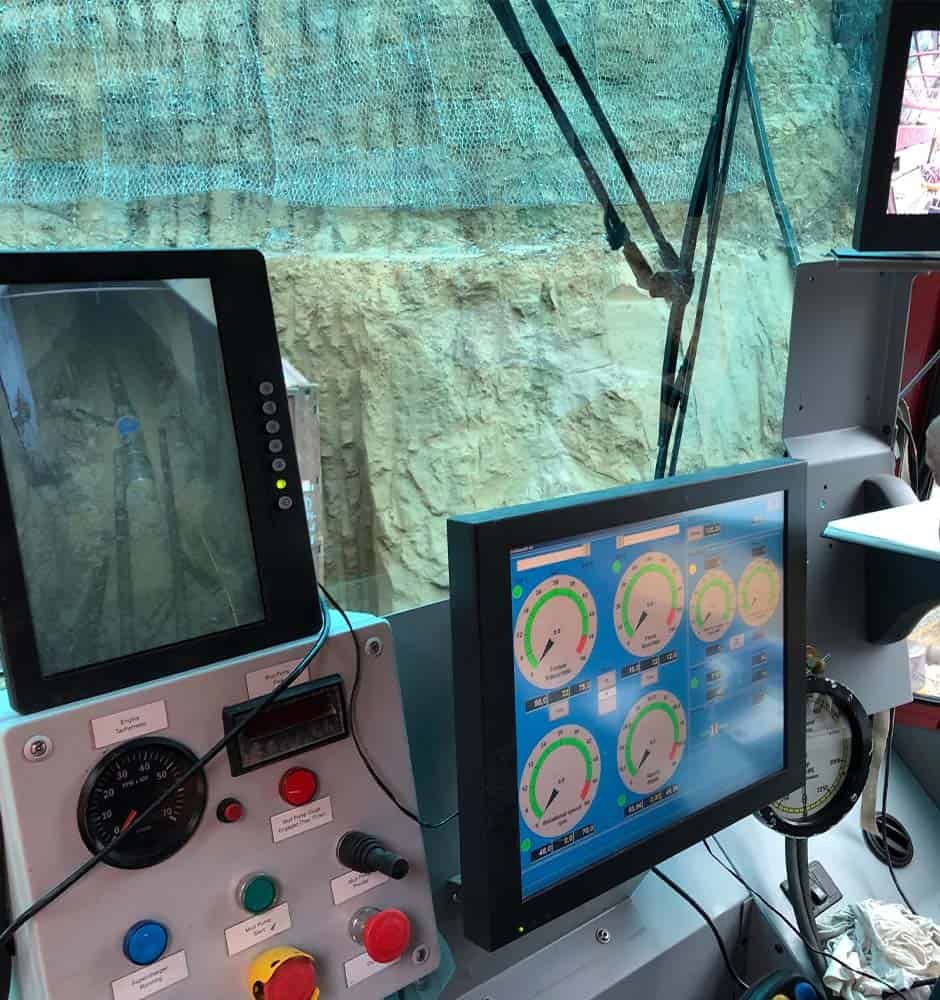

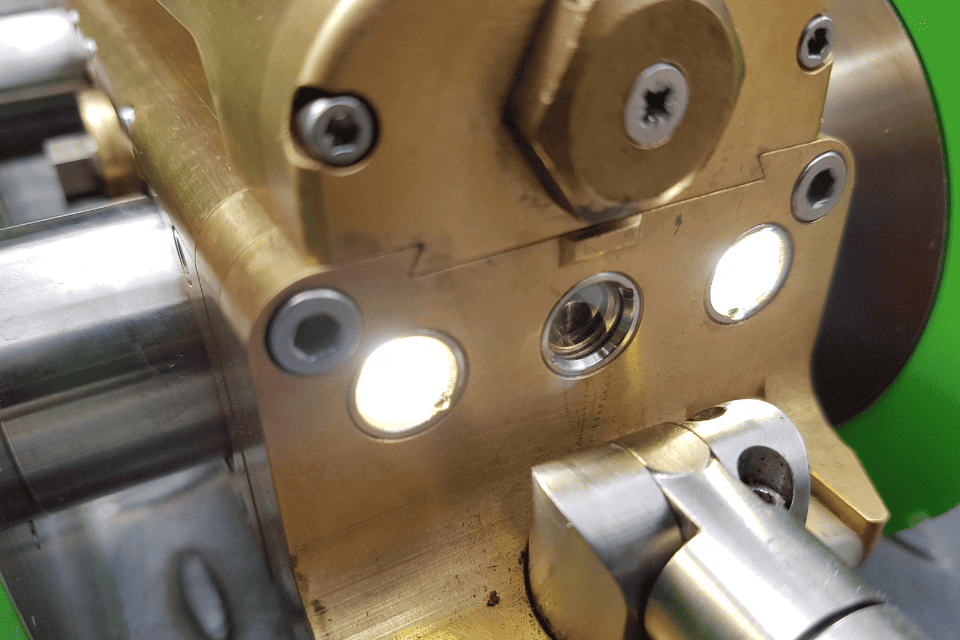

Troglotech T815 Crawler System (Tractor Camera)

Troglotech’s Crawler System is Lithium-Ion battery-operated and uses the latest technology for long mission times. The system is lightweight and highly portable which makes it very effective to use for both commercial and residential applications. As usual with Troglotech products, the system is highly robust with the crawler being machined from solid brass and stainless steel. With a range of quick-release wheel sets (the wheel bolts are locked into position for security) you can survey the full range of pipe sizes starting from 4” (100mm). The crawler is steerable and has a reversing camera and lights so that a survey can be performed in either direction. The batteries on the crawler have a long mission time (up to a full days inspection work) are quick-release and can be charged on-site or via a mains supply

Safety first

Troglotech’s systems are all battery operated so there are no dangerous voltages or generators required. The latest battery technology is used which provides a full days work from two crawler batteries and a single charge of the control unit battery.

Why battery power?

On most Troglotech Crawler Systems, up to 90% of the power is lost in the main cable. The cable could be increased in size with more copper to reduce this loss, but the crawler would need to be bigger and heavier to handle the increased load. In addition, the cable voltage at this size is often at lethal levels. The Troglotech’s Crawler System carries its own power source which means the main cable does not conduct any power. This aspect allows the unit to be much lighter in weight. The composition of the cable is mainly Kevlar and the three small conductors which only carry signals at safe voltages below 5V

Troglotech T815 Crawler System

ROBUST, SAFE, ZERO EMISSIONS, LIGHTWEIGHT

Specification

- The complete system is fully waterproof (IP67)

- Pan & Tilt and Reversing Camera as standard

- Extremely robust – crawler machined from solid brass and SS.

- Wi-Fi connectivity for immediate reporting to customer

- Suitable for pipe sizes 4” to 12” and above

- 300 metres Auto Drum of 4mm Kevlar cable

- Inclinometer and auto-steering to avoid turn-over.

- Complete system weighs only 26Kg.

- Locking Quick-Release wheel sets

- Powerful Sonde

Bespoke Specialised Pipeline Cameras

Given the extreme lengths and size of pipelines and tunnels that Hadlee & Brunton (H&B) work on with their trenchless technology, downhole vision is an essential tool, not only for the initial inspection works, but also during construction since this removes the need for manned entry and provides precise information for decision making.

Having struggled to find high-definition camera systems that could inspect distances in excess of 1km long and at pipe diameter ranges at both ends of the spectrum, H&B partnered with movie industry expert Piotr Wysocki (Fox) and have been developing highly specialised bespoke pipeline cameras for the last three years. The various cameras that have been developed to date have the ability to investigate, scan, measure to 0.01mm, 3D model and provide footage of pipelines that have internal diameters that range from 12mm through to 4000mm at distances of over 3km live stream and 14 km remote capture. On top of all of this, these cameras deliver movie standard image quality which far exceeds standard pipeline footage of the past.

Please refer to the images below showing the pipe scanning abilities of our bespoke cameras.

Digital Rope Counter (DRC)

Our advanced DRC has been designed to assist with work carried out in the field by counting the lineal meterage and speed of rope or cable that is being installed into the pipeline.

The biggest advantage of digital versus mechanical/analogue methods is the precision and clarity of the measurements displayed to the user.

The digital screen allows to check the measurements at any time, showing not only the length of the cable or rope but also the speed of entry in meters/min and km/h. Both those measurements allow the DRC to provide estimated time that’s needed to pull the required amount of cable/ or rope over the required distance.

The built-in high quality optical encoder ensures the precision of the taken measurements making it incredibly accurate even at long distances.

The DRC is capable of measuring ropes and cables with a maximum speed of 100km/h and length up to 99km and can measure between 1mm and 20mm diameter using a simple and quick height adjustment system.

The user-friendly simple design of the counter includes a rechargeable battery which will last for the entire day of operating which makes it portable to site and functional at sites with no power sources. It can also be operated while connected to the charger when power is available at the site.

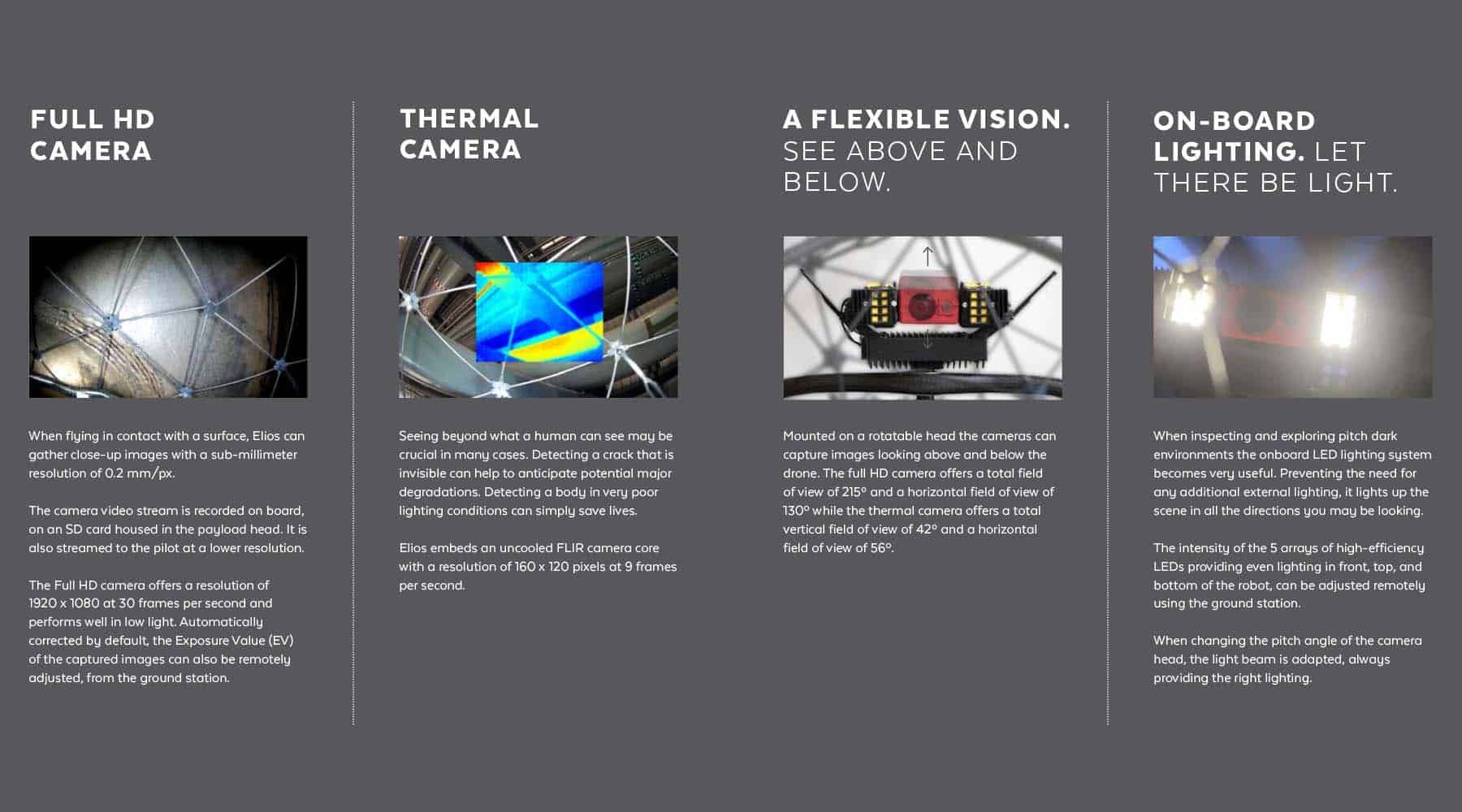

To add to the specialised cameras that have been developed, H&B also operate a Swiss inspection drone which allows for immediate and fast inspection of most confined and inaccessible spaces above 400mm in size.

Inspection Elios Drone

Hadlee & Brunton

Hadlee & Brunton prides itself on providing the highest level of

plumbing, drainage, drilling, roofing & maintenance service to the

public, local body and rural sectors, and we guarantee it.

Residential Services

Commercial Services

Info

Hadlee & Brunton Ltd

6 North Street, Timaru

(03) 684 3817

plumbers@hadleeandbrunton.co.nz