Pipe & Manhole Rehabilitation

Hadlee & Brunton offer trenchless pipe repair solutions to solve most issues that clients may have with pipelines and infrastructure assets. Whether the problem is isolated to a particular area or is consistent throughout a pipeline, we have the ability to assess and rectify the problem with our various trenchless solutions.

Pipe & Manhole

Rehabilitation

Pipe & Manhole Rehabilitation Services:

Amex Internal Pressure Seals

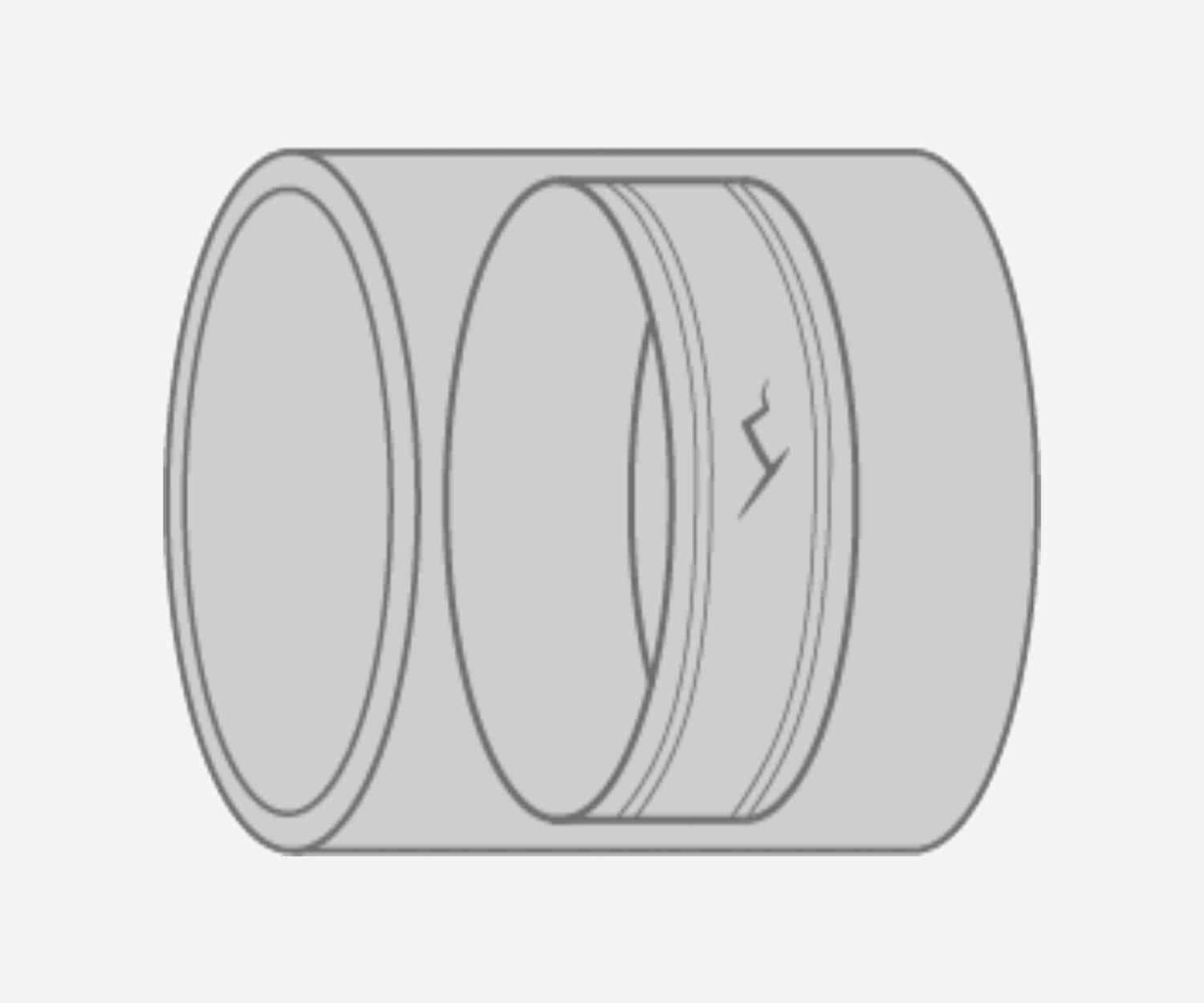

H&B are able to provide the full catalogue of Amex Sanivar’s pipe seals known as the “Amex Seals”. There are many different applications of the seals that can be used to repair broken or cracked pipes or displaced joints meaning the requirement for full pipeline replacement could be eliminated. There are options to custom make the seals to suit a specific pipe diameter or profile which can be designed and fabricated on a case-by-case basis.

How it works?

-

Amex Seals are composed of EPDM rubber providing both flexibility and endurance

-

With a size range from 600mm to 6000mm, there is something for almost every job

-

Depending on the damage, the width of the seal ranges from 180mm to 600mm for the Mono and even greater for the Vario!

-

Tested to withstand internal pressures of up to 25 bar and external pressure up to 8 bar

-

The seals can be installed in any type of pipe material and most shapes

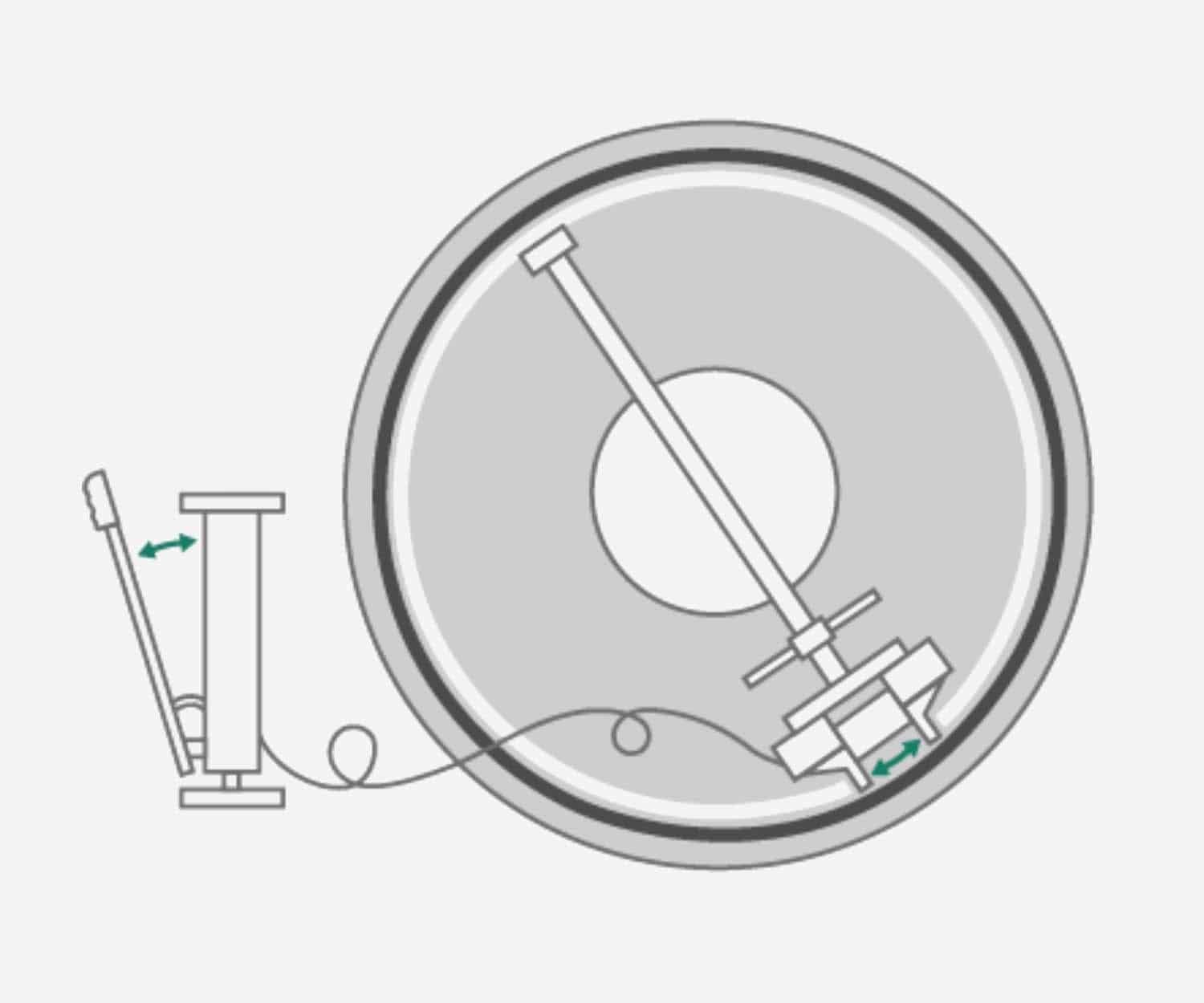

Installation Methodology

-

The seal is first put into place

-

The steel bands are then secured using a hydraulic tool

-

A shim is hit into the space created by the hydraulic tool in the steel band

-

The hydraulic tool is removed and the next steel band is placed

Main advantages

-

Use of hydraulic tool allows for quick and easy installation

-

Design life of over 50 years!

-

More than 30 years of experience between our technicians

-

Own production and service

-

No resin, no impregnation, and no curing needed

-

Can be custom made to fit your specifications

Amex-10 Mono

Amex-10 Mono technical specifications;

-

Diameter: DN 600-6000

-

Widths: 260mm, 366mm, 500mm

-

Pipe type: All

-

Applicable mediums: All

-

Max. internal pressure: 25 bar

-

Max. external pressure: 8 bar

-

Min. operating temperature: -30°C

-

Max. operating temperature: 130°C

Tests and Approvals

-

Potable Water: KTW, DVGW W 270, NSF 61, ACS, WRAS

-

General construction: DIBt Z-42.3-474

-

Resistance to hydro-pressure jetting: According to DIN 19523

-

Suitability test for raw materials: According to ISO 3384, ISO 188, DIN EN 681

-

Stress Relaxation: BS 903

-

Pressure test: 1,000 hours

-

Material design life Movement test: Liftetime FlowTight

Amex-10 Vario

Amex-10 Vario technical specifications;

-

Diameter: DN 600-6000

-

Width: 500mm+

-

Pipe type: All

-

Applicable mediums: All

-

Max. internal pressure: 25 bar

-

Max. external pressure: 8 bar

-

Min. operating temperature: -30°C

-

Max. operating temperature: 130°C

Tests and Approvals

-

Potable Water: KTW, DVGW W 270, NSF 61, ACS, WRAS

-

General construction: DIBt Z-42.3-474

-

Resistance to hydro-pressure jetting: According to DIN 19523

-

Suitability test for raw materials: According to ISO 3384, ISO 188, DIN EN 681

-

Stress Relaxation: BS 903

-

Pressure test: 1,000 hours

-

Material design life Movement test: Liftetime FlowTight

Amex-10 LEM

Amex-10 LEM technical specifications;

-

Diameter: DN 150-4000

-

Width: 260mm, 366mm, 500mm

-

Pipe type: All

-

Applicable mediums: All

-

Max. internal pressure: 25 bar

-

Max. external pressure: 8 bar

-

Min. operating temperature: -30°C

-

Max. operating temperature: 130°C

Tests and Approvals

-

Potable Water: KTW, DVGW W 270, NSF 61, ACS, WRAS

-

General construction: DIBt Z-42.3-474

-

Resistance to hydro-pressure jetting: According to DIN 19523

-

Suitability test for raw materials: According to ISO 3384, ISO 188, DIN EN 681

-

Stress Relaxation: BS 903

-

Pressure test: 1,000 hours

-

Material design life Movement test: Liftetime FlowTight

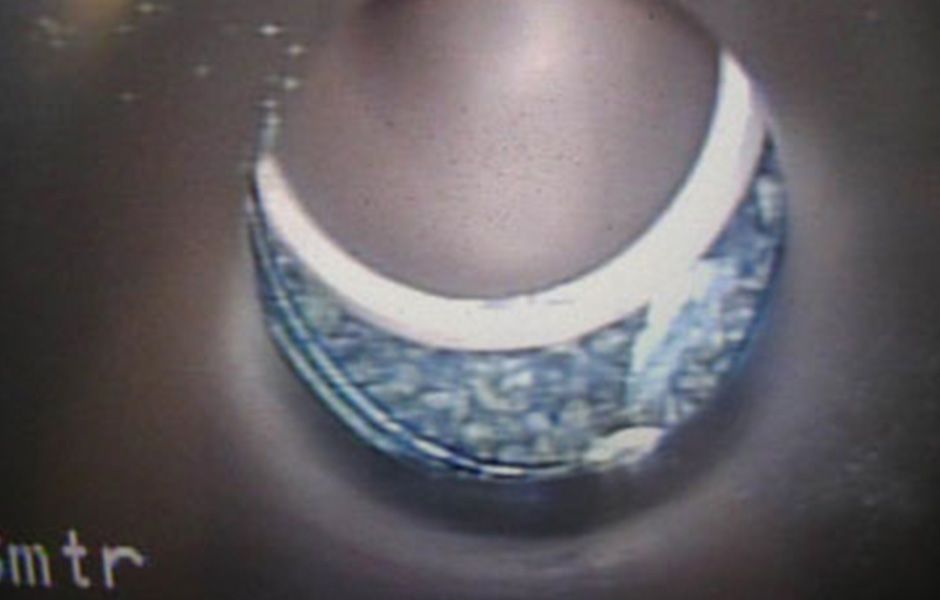

Structural Fibreglass Lining

Hadlee & Brunton specialise in patching existing drainage pipes with a fibreglass repair. This is a cost effective and easy to use solution for the permanent and watertight repair of damaged pipes, without the need for excavation work. We can patch a damaged section of pipe over 40m from where we enter the drain. We can repair most types of pipes including ceramic / clay, concrete, uPVC, metal and much more, from 25mm up to 1200mm in diameter. The Fernco Pipe Doctor is installed internally and eradicates the need for costly, disruptive and time consuming excavation work therefore enabling both vehicle and pedestrian traffic to move freely without realising drainage and sewer work is being carried out underground.

Benefits

-

Quick and easy to use no dig application (No disruption)

-

Permanent and watertight pipe repair which can be used for root intrusion issues

-

The drains can remain running during the installation

-

Environmentally and ecologically friendly

-

The only WRc Approved patch repair in the marketplace, also meeting international standards

-

Reduces site wastage

-

The Fernco Pipe Doctor has been tested using the Fernco installation equipment and a guarantee of 10 years has been established for the materials.

Manhole Rehabiltation

100% SOLIDS STRUCTURAL EPOXY COATING SYSTEM

Even in the presence of damp substrates, Ultracoat will effectively adhere to any surface, eliminating and preventing infiltration and leaving a smooth finish with enhanced flow characteristics. Application of Ultracoat is also structurally reinforcing – independent testing showed an increase in compressive strength of concrete pipes of 20%.

After application, for example for bund rehabilitation, the Ultracoat 100% solids epoxy coating system is chemical resistant from pH 2-14. This includes complete resistance to high levels of hydrogen sulphide, up to 40% concentration of nitric acid, acetic acid, calcium chloride and others.

Particularly relevant for manhole rehabilitation and other confined spaces, the Ultracoat system is free from VOCs (volatile organic compounds), meaning breathing apparatus is not required. It is free from solvents and no primer coat is required – application is quick and easy and a manhole chamber or culvert can be back in operation within hours of the project starting.

The Ultracoat epoxy coating system was developed by Danny Warren of Warren Environmental in the USA over 35 years ago and has been used to renovate over 50,000 manholes and kilometres of pipes and tunnels – WITH ZERO FAILURES.

The Ultracoat system is CE marked and complies with the standard BS EN 1504-2:2004 “Products and systems for protection and repair of concrete structures – part 2 surface protection systems”.

The following are the key

applications for the Ultracoat system:

ULTRACOAT – MANHOLE REPAIRS

ULTRACOAT – TUNNELS

ULTRACOAT – CULVERTS

ULTRACOAT – LARGE CHAMBERS

ULTRACOAT – BUND LINING

TESTING AND ACCREDITATIONS

The ultracoat system has been tested to the following standards

-

ASTM C297Tensile Strength

-

ASTM D2240Durometer Hardness

-

D2584Volatile Matter Content

-

D4414Wet Film Thickness by Notch Gages

-

D4541Pull-off Strength of Coatings Using a Portable adhesion Tester

-

D4541Concrete Failure Chemical Resistance to: Sulfuric Acid, 70%

-

D543Resistance of Plastics to Chemical Reagents

-

D543Water Vapor Transmission of Organic Coating Films

-

D543Immersion Service

-

D638Flexural Properties of Unreinforced and Reinforced Plastics

-

ASTM D638Tensile Properties of Plastics

-

ASTM D638Flexural Strength

-

ASTM D638Tensile Elongation

-

ASTM D638Tensile Strength

-

ASTM D695Compressive Properties of Rigid Plastics

-

ASTM D695Compressive Strength

-

ASTM D695Flatwise Tensile Strength Of Sandwich Constructions

-

ASTM D790Flexural Properties of Unreinforced and Reinforced Plastics

-

ASTM D790Bond Strength – Concrete

-

ASTM D790Flexural Modulus

-

ASTM D790Flexural Strength

-

ASTM E84Test Method for Surface Burning Characteristics of Building Materials

Hadlee & Brunton

Hadlee & Brunton prides itself on providing the highest level of

plumbing, drainage, drilling, roofing & maintenance service to the

public, local body and rural sectors, and we guarantee it.

Residential Services

Commercial Services

Info

Hadlee & Brunton Ltd

6 North Street, Timaru

(03) 684 3817

plumbers@hadleeandbrunton.co.nz